|

Material Innovations Inc. |

|

Huntington Beach, Ca 92649 Phone: 714 373-3070 Cell: 714 393-1728 |

|

Thermal expansion testing |

|

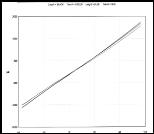

MII offers Dilatometer and Non-Destructive Coefficient of Thermal Expansion Testing (CTE): MII houses a dilatometers and non-destructive surface distortion test equipment to determine the coefficient of thermal expansion (CTE) of materials. With monolithic and homogenous materials, a dilatometer measurement provides an accurate measure of CTE within the entire specimen in generally one direction per test. With exotic material such as printed circuit boards (PWB’s) or fiber composite materials, where constraining fibers may not be uniformly distributed, the small test specimens used for dilatometry determination may not be representative of the CTE at the surface. The surface distortion method, ‘CTE By Surface Strain’, is an ideal method when considering CTE mismatch between parts joined by fasteners, adhesives or brazing.

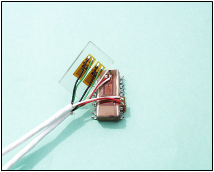

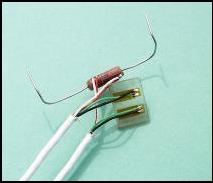

For surface strain CTE measurement, strain gages are attached directly to the test specimen surfaces. As the specimen is heated in an environmental chamber, the strain and temperature data are continuously acquired and processed via data acquisition. For isotropic materials, and composites with uniform constituent distributions, strain gauge CTE results are identical to those found using a dilatometer. This method is non-destructive and processes four channels (e.g.. X and Y on each side of a plate) simultaneously.

Test temperature capability for each method is as follows: · Dilatometry: -300°F to 1500°F · Surface Strain CTE: -275°F to 475°F · Extended test temperature ranges possible (please call) |